The couple met while studying textile design at RMIT. Both drawn to creative vocations, they each explored a variety of mediums before settling on cloth. They developed their drawing skills and understanding of repeats in a time prior to computer assisted imaging, then honed a variety of dying and print skills at Vixen Clothing during the brand’s hey day, before eventually opening the doors to their own textile printing business.

Jason and Nadia have printed client work as well as their own textile designs ever since. The screens of many well known fashion, furnishing and yardage labels have been pulled across the Printink Studio tables, including Lumiere Art & Co, Fable Baby, Midas Shoes and Alexi Freeman. By meeting countless client briefs, the pair have have developed a multitude of fabric decoration skills that including devore and foiling. Now primarily focused on pigment printing (water soluble Permaset inks), they also continue to draw from a wealth of dying skill, working with silk, wool and every type of fibre in between.

“I think the first few years were just discovering and experimenting with what we wanted to do. Working out what direction we wanted to go,” Jason reflects. “We started doing a lot with fashion because we found there was a need for it. A lot of people wanted to do textile printing for their own fashion labels. I guess that is part of our background too, with our time at Vixen. Then we wanted to start our own work, so we kind of needed the other printing jobs to keep going.”

They built their brand Tinker alongside printing work for their Printink clients. “We always ended up doing a lot of print work, rather than working on our own stuff,” Nadia explains. However, over the years this focus has slowly shifted in response to changes in industry and technology, allowing the couple to prioritise designing and printing for Tinker. “We have changed our approach in the last few years,” explains Jason, “so we have focused a lot more on our work, and we are doing ranges and getting new stuff out every six months and doing trade shows and that kind of thing. In the end doing our own work has helped us, as the printing work has slowed down a lot,” he adds.

She explains that a custom print is often unaffordable for brands who compete against cheaper imports. “So we are finding a lot of clients that we do do work for, especially prints, are usually smaller labels,” Jason expands, “or a bit more bespoke – a bit more one off. Which is kind of nice, that way we can work together on projects.”

“It is nice that you can work together on smaller things,” Nadia echoes, “and do work that is a little bit more specialised. We have done all sorts of bits and pieces – you can work with film people for costumes or do a lot more bespoke things, where you get to do a few more techniques, and things that you can’t do as production – or do smaller printer runs, which is nice. It mixes it up and you get to to tap into all those skills you do have,” she says.

Calm, unassuming and entirely approachable, these two completely play down their shared wealth of experience. As they start sharing their vast and industrially beautiful space, they point out paint racks of ink stacked in colour groupings and labelled with the correct Pantone code from jobs gone by, machines to expose screens, a small heat setter, large wash trough, industrial fans and a generous storage space for large screens that hold their own work, as well as that of their clients. These guys have been tinkering with these tools of the trade for more than a decade. They casually share details of each intricate process and boxes of samples from countless jobs without a trace of ego – perhaps even awareness – of just how much they know.

But it is the 22m tables that dominate the long space. Bordered by extensive frosted glass panes and vast industrial ceilings, a subtle light fills the studio, making the considerable space feel friendly, even on a winter’s day. During the summer, the pair love to throw the windows open and “let the outside in”, especially on a Saturday morning, where they often find they do their most creative work.

As with most labels, the proportion of this creative time is slim in comparison to the time spent managing their business and making products. “We would love to sit there all day and just design, but we literally give ourselves a week to come up with a new range,” says Jason. “It’s a little longer than that,” says Nadia, “but you do churn and burn when you are in the process. It is a very intense zone – one thing flows after another – quickly, because not only do you have to design, you have to experiment with your printing and how you are going to then take it to product, so it is a whole stage.”

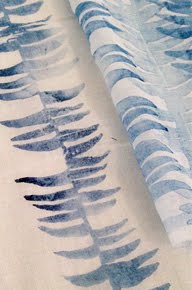

In this fast and fleeting space, Jason and Nadia often start their designs with hand drawings, referencing the inspiration wall they have been drawing together on boards in their upstairs office space. They both believe that first touch by hand adds a level of depth and integrity to their designs, which are then scanned and manipulated using Photoshop and Illustrator. Jason describes Tinker’s designs as “a celebration of colour, nature, imagination, nostalgia and the mesmeric beauty of patterns.” Bright colours, shapes and florals stretch across canvas, cotton and linen, often interspersed with flashes of special finishes, like gold metallic dots, that ultimately “imbue environments with lightness, spark and cheer.”

The couple recognise that they are in an an enviable position. With all of the tools, skill and space they could ever need at their disposal, they sample many finishes, colours and fabrics before settling on their final designs. This process of trial and error leads them to determine the product line they will make from each new fabric.

“Designing is one element,” explains Nadia, “but I think we always look to see, within our product range, what can we offer that not everyone else has. Especially when you are competing in a market like this – there are a million, trillion cushions out there – not only is it the design that has to make it different, but what else is going to make it seem a little bit different as well. So we try to use a few different techniques – such as using a little bit of foiling – just to make it a little bit different.”

“We’ll choose a palette, and then work back with a few things. We are very tactile, in that we print every single sample, as opposed to some of our clients, who come to us and say ‘here’s my design, and I’ll have that Pantone colour’.”

As with most designers, these swatches ‘travel’ before being finalised, often “going home” with the pair to see how it plays out in a different environment. The couple decide what type of product the samples are most suited to, before integrating them into a new range, which includes table cloths and runners, cushions, scarves, totes, children’s wear, baby blankets and the eventual placement of every design on a limited range of fancy wallpaper.

With ideas constantly in mind, an eclectic mix of client designs continue to cross their tables each day, a sight that is surely a wonderful inspiration for the couple’s ginger haired little girl, who has been with the couple at the studio since “day one”. Completely at home with their local community, and the ever changing nature of their work, this is truly a family venture, which perhaps explains why it feels so comfortable and relaxed.

Although admitting that the industry is not always easy, Jason and Nadia seem to be leveraging all of their experience and know-how into directions that continue to delight and inspire them. Jason acknowledges “the endless possibilities” with an obvious fondness for their chosen medium, with plans to expand Tinker’s product range and reach in the coming years. Paying “special attention to the kids and accessories ranges,” Tinker’s children’s wear will soon be found in Japan, and their wallpaper is set to “get a total overhaul with all new designs and colour ways added to the range,” says Jason.

One thing is for sure. These guys won’t stay still as they continue to draw from the past and look to the future. Just like the neighbourhood hive of activity that constantly surrounds them.

Photos by Jodie Cheetham @threadbound. If reposting, please also share these credits.